Features

-

1

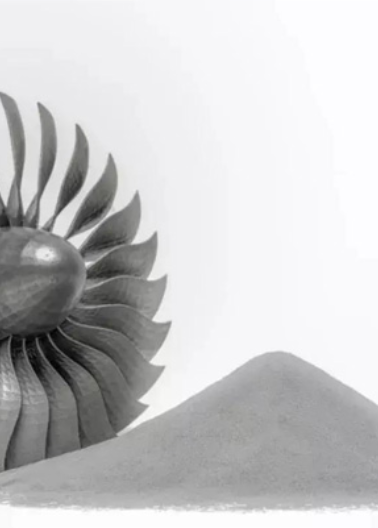

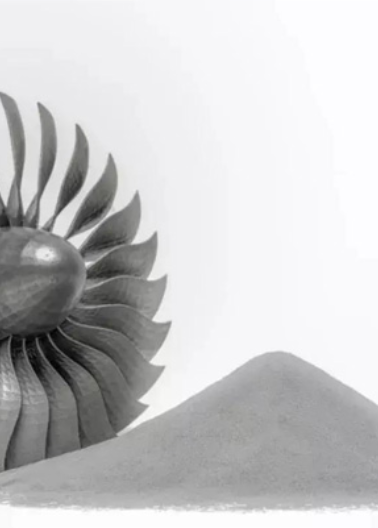

The tailored Laseradd Di-Metal machine that suits your specific requirements.

-

2

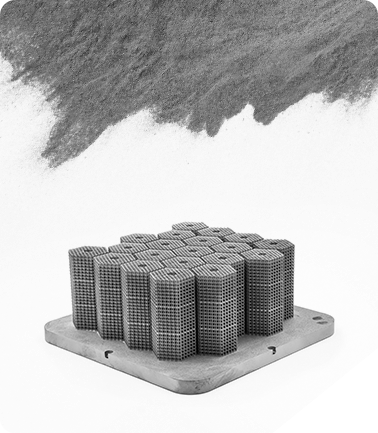

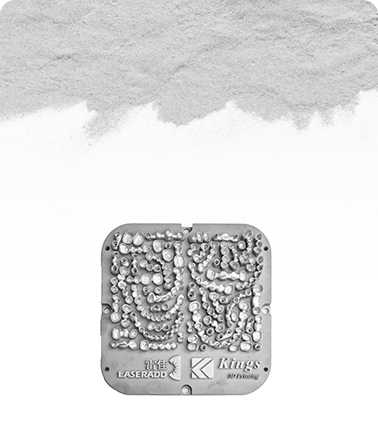

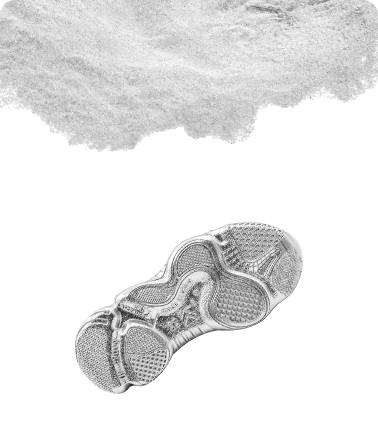

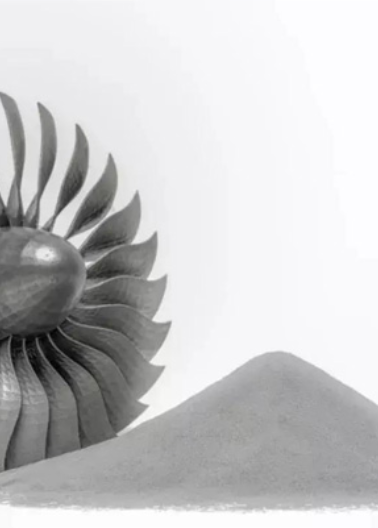

Metal powder that defines the subsequent functionality and purpose of a component.

-

3

Meticulously crafted Laseradd parameters, bridging the critical gap.

Advantages

-

Laseradd Materials

Thanks to our open architecture, we proudly offer the most extensive metal portfolio among metal AM companies. Through collaboration with our partners, we have successfully utilized over 30 materials to date. If you are searching for a specific material or interested in acquiring any powder through us, please feel free to reach out to our Materials Team!

-

Laseradd Parameters

The crucial link between the printer and metal powder is what leads us into the core of SLM printing: our meticulously designed and verified parameters for Laseradd metal powders. These powders are pivotal in producing functional parts with predictable and reliable functionality. We've streamlined the categories, offering from high-resolution complex details (High Precision) to the highest build rates (Production Speed), or a fusion version in between (Blended Version).

-

Laseradd Powder Handling Equipment

We aim to provide every customer who purchases a metal printer and engages in metal printing with the most effective powder handling solutions. That's why we equip our setup with a vacuum explosion-proof vacuum cleaner, a powder drying box, and a sieve machine with energy-saving replaceable screens. This not only enhances powder utilization but also contributes to the conservation of clean and sustainable energy resources.

-

Al

-

AISi10Mg

Laseradd's AlSi10Mg, an aluminum-based alloy, is a widely recognized choice in the additive manufacturing industry for producing functional components and prototypes. AlSi10Mg is commonly selected for applications where excellent mechanical properties and lightweight characteristics are essential.

Key Material Features:

- ◆ Exceptional Corrosion Resistance

- ◆ High Electrical Conductivity

- ◆ Impressive Dynamic Toughness

- ◆ Outstanding Thermal Conductivity

- ◆ Aerospace

- ◆ Automotive

- ◆ Engineering

- ◆ Heat Exchangers

Common Application Fields:

Co

-

CoCrMoW

Laseradd presents CoCrMoW, a cobalt-based alloy powder known for its excellent flowability, high sphericity, low oxygen content, minimal satellite particles, and high tap density. The particle size distribution includes 15-53 μm, 15-45 μm, 50-150 μm, D50 10-15 μm, and D50 5-7 μm. This metal powder is utilized in various 3D printing applications in industries such as aerospace, heat exchangers, automotive, medical devices, and defense.

Key Material Features:

- ◆ High sphericity

- ◆ Low oxygen content

- ◆ Minimal satellite particles

- ◆ High tap density

- ◆ Aerospace

- ◆ Tooling

- ◆ Automotive

- ◆ Medical devices

- ◆ Defense

Common Application Fields:

CoCrMo

Laseradd offers CoCrMo, an alloy composed of cobalt, chromium, and molybdenum, with a wide range of applications. Due to its outstanding biocompatibility, CoCrMo is widely employed in the medical industry for the manufacturing of implants and prostheses. This material is also utilized to fabricate components for use in high-temperature environments, such as jet engines.

Key Material Features:

- ◆ Exceptional biocompatibility

- ◆ High-temperature resistance

- ◆ Resistant to thermal fatigue

- ◆ Excellent oxidation resistance

- ◆ Medical

- ◆ Aerospace

- ◆ Energy

- ◆ Turbine parts

Common Application Fields:

Cu

-

CuSn10

CuSn10 is a copper alloy recognized for its remarkable attributes, including high hardness, exceptional wear resistance, resistance to seizing, good castability, and reliable machining performance. It also demonstrates corrosion resistance in both atmospheric and freshwater environments. The ZCuSn10Pb1 cast copper alloy is well-suited for wear-resistant components that operate under high loads (up to 20 MPa) and at high sliding speeds (up to 8 m/s). Such components encompass connecting rods, bushings, bearings, gears, and worm wheels.

Key Material Features:

- ◆ High hardness

- ◆ Exceptional wear resistance

- ◆ Good castability

- ◆ Reliable machining performance

- ◆ Corrosion resistance

- ◆ Reliable machining performance

- ◆ Machinery and equipment

- ◆ Medical

- ◆ Optics

- ◆ Aerospace

- ◆ Molding

Common Application Fields:

CuCrZr

Laseradd introduces CuCrZr, a copper alloy known for its minimal alloying element content, resulting in an exceptional balance of mechanical and conductive properties. Following heat treatment, CuCrZr can achieve up to 92% IACS in electrical conductivity while maintaining a high ultimate tensile strength of up to 300 MPa. The inclusion of chromium and zirconium enhances strength and hardness at elevated temperatures, making it an ideal choice for applications like rocket engines.

Key Material Features:

- ◆ Highest electrical conductivity among Laseradd copper alloys

- ◆ High-temperature stability for strength and hardness

- ◆ Improved strength compared to pure copper

- ◆ Aeronautics and space

- ◆ Electrical engineering

Common Application Fields:

Fe

-

S136

Laseradd's S136 steel is a high-quality stainless steel that performs exceptionally well in its quenching and tempering state (hardness of 48-54HRC). Here are some of its usage characteristics and considerations:

Key Material Features:

- ◆ Corrosion resistance

- ◆ High hardness

- ◆ Good machinability and wear resistance

- ◆ Mold manufacturing

- ◆ Automotive

- ◆ Electronics

- ◆ Medical

- ◆ Aerospace

- ◆ Household appliances

Common Application Fields:

302

Laseradd's 302 stainless steel is essentially a variant of 304 stainless steel with a higher carbon content, which can be cold-rolled to achieve higher strength. 302B is a stainless steel with a higher silicon content, offering excellent high-temperature oxidation resistance. 303 and 303Se are free-cutting stainless steels containing sulfur and selenium, respectively, ideal for applications that demand easy machining and high surface finish.

Key Material Features:

- ◆ Good mechanical properties

- ◆ Corrosion resistance

- ◆ Machinery

- ◆ Electronics

- ◆ Electrical equipment

- ◆ Instruments

- ◆ Food machinery

- ◆ Shipping

- ◆ Automotive

Common Application Fields:

304

Laseradd's 304 stainless steel is a commonly used material in the stainless steel family, with a density of 7.93 grams per cubic centimeter. It is also known as 18/8 industrial stainless steel, indicating it contains over 18% chromium and over 8% nickel. This material is characterized by good processability and high toughness, making it widely applicable in industrial, furniture, and food and medical industries.

Key Material Features:

- ◆ Environmentally friendly and sanitary

- ◆ Wear-resistant

- ◆ Low-temperature resistance

- ◆ Excellent thermal expansion and insulation performance

- ◆ Industry-certified

- ◆ Plate heat exchangers

- ◆ Household items

- ◆ Automotive components

- ◆ Medical equipment

- ◆ Building materials

- ◆ Chemical, food industry, agriculture, and marine components

Common Application Fields:

H13 (1.2344)

Laseradd's H13 (1.2344) is a chromium-containing martensitic tool steel. This material is ideal for tooling applications demanding exceptional strength and toughness.

Key Material Features:

- ◆ High tensile strength

- ◆ Moderate corrosion resistance

- ◆ Resistance to thermal fatigue cracking

- ◆ Injection molding

- ◆ Tooling

Common Application Fields:

1.2709

Laseradd's 1.2709 mold steel is a high-strength, high-toughness tool steel primarily used for manufacturing molds and mold components. Its chemical composition includes elevated levels of molybdenum, cobalt, and chromium elements, enhancing the steel's hardness, wear resistance, as well as tensile strength and toughness.

Key Material Features:

- ◆ Hardness and wear resistance

- ◆ Corrosion resistance and machinability

- ◆ Heat treatment and surface treatment

- ◆ Plastic molds

- ◆ Die-casting molds

- ◆ Stamping molds

- ◆ Extrusion molds

- ◆ Milling tools, drills, and more

Common Application Fields:

316L(1.4404)

Laseradd's stainless steel 316L is an austenitic high-chromium steel with exceptional processability on Laseradd's additive manufacturing machines. 316L is commonly employed in applications that demand excellent mechanical properties and outstanding corrosion resistance, particularly in chloride-rich environments.

Key Material Features:

- ◆ Outstanding corrosion resistance

- ◆ High strength at elevated temperatures

- ◆ High ductility

- ◆ Aerospace

- ◆ Automobile

- ◆ Surgical instruments

- ◆ Food industry

- ◆ Offshore installations

Common Application Fields:

15-5PH(1.4545)

Laseradd's 15-5PH is a martensitic precipitation-hardening stainless steel renowned for its excellent performance on Laseradd's additive manufacturing machines. It is well-suited for applications that demand high strength and hardness, accompanied by moderate corrosion resistance. This alloy is the ferrite-free alternative to 17-4PH.

Key Material Features:

- ◆ Precipitation-hardenable

- ◆ Exceptional tensile strength

- ◆ Moderate corrosion resistance

- ◆ Aerospace

- ◆ Medical

- ◆ Chemical / Petrochemical

- ◆ Paper / Metalworking industries

Common Application Fields:

SS420

420 stainless steel is a "tool-grade" martensitic steel, reminiscent of the earliest stainless steel known as high-chromium steel. It possesses reasonable wear resistance, corrosion resistance, and high hardness. 420 stainless steel falls into the lower price range of stainless steel grades and is suitable for applications with general stainless steel requirements.

Key Material Features:

- ◆ Wear resistance

- ◆ Corrosion resistance

- ◆ High hardness

- ◆ Precision machinery

- ◆ Bearings

- ◆ Electrical equipment

- ◆ Machinery

- ◆ Instruments

- ◆ Instrumentation

- ◆ Transportation

- ◆ Household appliances

Common Application Fields:

NI

-

18Ni300

Laseradd offers 18Ni300, a low-carbon martensitic aging steel known for its superior strength, toughness, and wear resistance compared to conventional steel materials. It is commonly used in the production of components for the automotive, medical, and mechanical industries. Due to the small size and complex shapes of these parts, conventional powder metallurgy processes often struggle to achieve the desired results or deliver satisfactory performance. This significantly increases production costs. However, the application of the Selective Laser Melting (SLM) method provides an effective solution.

Key Material Features:

- ◆ Maintains excellent toughness and high fracture toughness under conditions of ultra-high strength and high hardness.

- ◆ These steels do not harden during cold working, and exhibit minimal deformation during aging heat treatment.

- ◆ Good welding properties.

- ◆ The surface can also undergo nitriding treatment.

- ◆ Aerospace

- ◆ Energy

- ◆ Marine

- ◆ Automotive

- ◆ Tooling

Common Application Fields:

GH3536

Laseradd is proud to offer GH3536, a high-temperature nickel-based alloy with a high iron content, primarily strengthened by chromium and molybdenum solid solution. This alloy boasts excellent resistance to oxidation and corrosion, delivering moderate long-term and creep strength below 900°C. It also exhibits favorable cold and hot working properties, as well as exceptional weldability.

Key Material Features:

- ◆ Excellent Processability

- ◆ Moderate Long-term and Stress Rupture Strength at 900°C

- ◆ Outstanding Laser Welding Properties, as well as Cold and Hot Forming Abilities

- ◆ Superior Oxidation and Corrosion Resistance, suitable for components in aircraft engine combustion chambers and augmented combustion chambers operating below 900°C for prolonged durations, with short-term working temperatures reaching up to 1080°C.

- ◆ Aerospace

- ◆ Energy

- ◆ Nuclear Industry

- ◆ Chemical Industry

- ◆ Turbines

Common Application Fields:

IN625(GH3625)

Laseradd proudly offers IN625, a precipitation-hardenable nickel-based material meticulously engineered with the inclusion of chromium, molybdenum, and niobium. IN625 represents a quintessential choice for fabricating components employed in aircraft engines, characterized by service temperatures under 650 °C.

Key Material Features:

- ◆ Remarkable High Strength

- ◆ Exceptional Ductility

- ◆ Outstanding Creep Rupture Strength below 700 °C

- ◆ Superlative Corrosion Resistance

- ◆ Aerospace

- ◆ Energy

- ◆ Chemical Industry

- ◆ Turbine Parts

Common Application Fields:

IN718

Laseradd presents IN718, a precipitation-hardenable nickel-chromium alloy renowned for its exceptional properties. Offering impressive tensile, fatigue, creep, and rupture strengths, even at temperatures up to 700 °C, IN718 stands as a pivotal alloy for manufacturing components utilized in aircraft engines, (gas) turbines, and various high-temperature applications.

Key Material Features:

- ◆ Exceptional High Strength

- ◆ Good Ductility

- ◆ Outstanding Mechanical Properties up to 700 °C

- ◆ Superb Oxidation Resistance

- ◆ Aerospace

- ◆ Energy

- ◆ Chemical Industry

- ◆ Turbine Parts

Common Application Fields:

TI

-

TC-4

Laseradd's TC4 titanium alloy, a type of A-3 titanium alloy developed in the United States in 1954, contains 6% α-stabilizing element Al and 4% β-stabilizing element V. The nominal composition of TC4 titanium alloy has an aluminum equivalent of 7.0 and a molybdenum equivalent of 2.9, with 10% to 15% β-phase content in the annealed state.

Key Material Features:

- ◆ Moderate room temperature and high-temperature strength

- ◆ Excellent creep resistance and thermal stability

- ◆ Fatigue performance and resistance to crack propagation in seawater

- ◆ Fracture toughness and resistance to hot-salt stress corrosion

- ◆ Lower sensitivity to oxygen compared to TC2 and TC1 alloys

- ◆ Aerospace

- ◆ Medical

- ◆ Chemical and petroleum industries

- ◆ Shipbuilding

Common Application Fields:

TA15

Laseradd introduces TA15, a near-alpha titanium alloy infused with aluminum and zirconium additives. Boasting an extraordinary combination of high specific strength, load-bearing capacity, and temperature resistance, TA15 components are the go-to choice for robust applications in aircraft and engine construction.

Key Material Features:

- ◆ Exceptional Mechanical Properties, even at high temperatures

- ◆ Remarkable Load-Carrying Capability, even under multiaxial stress conditions

- ◆ Outstanding Specific Strength

- ◆ Excellent Weldability

- ◆ Aerospace

- ◆ Engineering

Common Application Fields:

Ti6AI4V

Laseradd's Ti6Al4V, the world's most renowned titanium-based alloy, stands out for its exceptional attributes. Thanks to its remarkable combination of high strength, low density, and superior corrosion resistance, Ti6Al4V is ideally suited for the production of components in the aerospace and automotive sectors, as well as various biomedical applications.

Key Material Features:

- ◆ Excellent Corrosion Resistance

- ◆ Impressive Specific Strength

- ◆ Exceptional Cycle Fatigue Strength

- ◆ Outstanding Toughness

- ◆ Aerospace

- ◆ Automotive

- ◆ Medical

- ◆ Energy

Common Application Fields:

W

-

Tungsten(W)

Tungsten is an extremely hard, steel-gray to white transition metal. Tungsten is a refractory metal and is mostly found in nature in the form of compounds with other elements rather than in its pure form.

Key Material Features:

- ◆ High hardness

- ◆ High melting point

- ◆ Relatively stable chemical properties

- ◆ Manufacturing filaments and high-speed cutting alloy steels

- ◆ Superhard molds

- ◆ Optical instruments, chemical instruments

- ◆ China has the world's largest tungsten reserves

Common Application Fields:

-