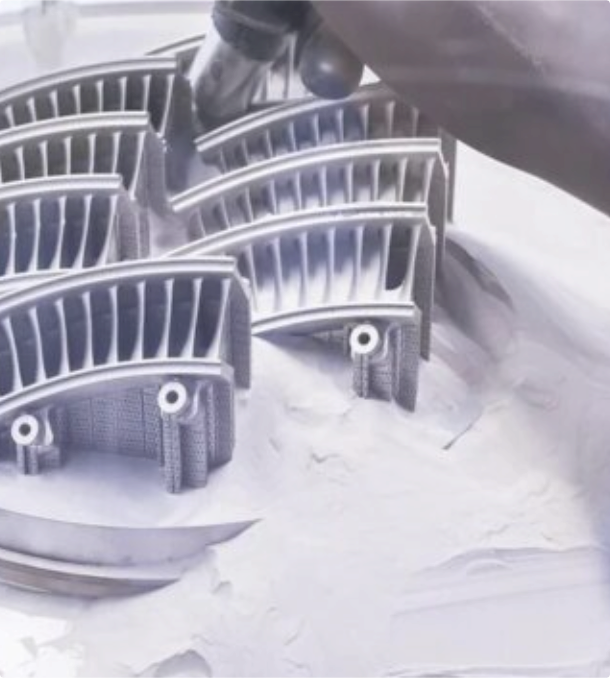

Additive Manufacturing Solutions for Research & Development

Laseradd is at the forefront of collaborative innovation, partnering with esteemed academic institutions, technological centers, and research facilities to propel the evolution of laser powder bed fusion for metals. Our selective laser melting (SLM) systems offer open architecture that grants users unparalleled control over every aspect of the printing process, facilitating efficient optimization and customization to suit specific needs. We have empowered researchers to delve into research in additive manufacturing design, topology optimization, lightweighting, functional integration, alloy development, and advanced production methods. Let’s explore how Laseradd’s SLM solutions can elevate your R&D capabilities and push the boundaries of your research fields.

Laseradd Material for R&D Applications

Laseradd provides an extensive selection of high-quality metal powders that are compatible with our SLM systems, frequently utilized in research applications. All materials supplied by Laseradd undergo rigorous qualification processes to ensure their chemical composition, spherical structure, particle size distribution, dryness, and flowability meet stringent standards. We furnish validated process parameters for all our metal powder variants on our machinery, offering comprehensive support to our customers in alloy development endeavors.OUR MATERIAL PORTFOLIO COMPRISES

-

1

Nickel-Based Alloys: Laseradd IN625, Laseradd IN718, and Laseradd HX

-

2

Titanium-Based Alloys: Laseradd TiAl6V4

-

3

Aluminum-Based Alloys: Laseradd AlSi10Mg