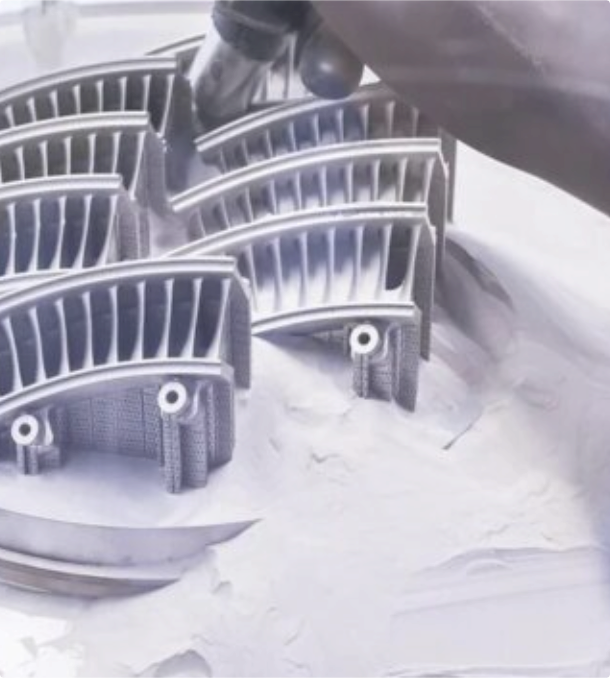

Metal 3D Printing Solutions for Automotive

SLM 3D printers are revolutionizing the automotive sector by driving product development through additive manufacturing. Major OEMs and Tier 1 suppliers are leveraging this technology to establish scalable, on-demand local supply chains, enabling faster market entry. Through topology optimization, SLM empowers automotive manufacturers to enhance both cost-effectiveness and functionality, optimizing part designs for superior performance. Laseradd SLM Technology serves as a crucial bridge between prototyping and serial production, addressing production volumes that would otherwise be expensive and time-consuming to achieve, thereby unlocking new levels of efficiency and innovation in the automotive industry.

Laseradd Material for Automotive Applications

Laseradd offers a wide range of qualified metal powders compatible with our SLM systems. All materials provided by Laseradd are qualified for their chemistry, spherical structure, particle size distribution, dryness, and flowability.OUR MATERIAL PORTFOLIO COMPRISES

-

1

Al-Based Alloys: AlSi10Mg and ALSi7Mg

-

2

Ni-Based Alloys: Inconel 625

-

3

Fe-based Alloys: 1.2709, 316L (1.4404)