DATA SHEET

Advantages

Warning: Invalid argument supplied for foreach() in /www/wwwroot/laseradd3d.com/wp-content/themes/laseradd/single-product.php on line 52

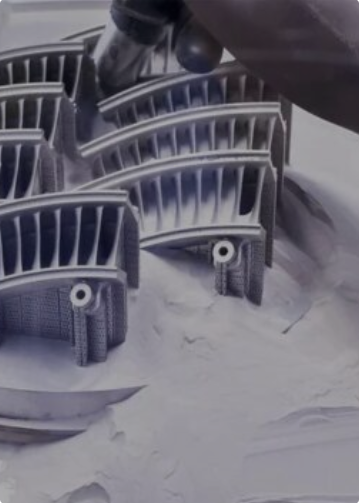

Samples

Warning: Invalid argument supplied for foreach() in /www/wwwroot/laseradd3d.com/wp-content/themes/laseradd/single-product.php on line 75

ACCESSORIES

Warning: Invalid argument supplied for foreach() in /www/wwwroot/laseradd3d.com/wp-content/themes/laseradd/single-product.php on line 99

Warning: Invalid argument supplied for foreach() in /www/wwwroot/laseradd3d.com/wp-content/themes/laseradd/single-product.php on line 117